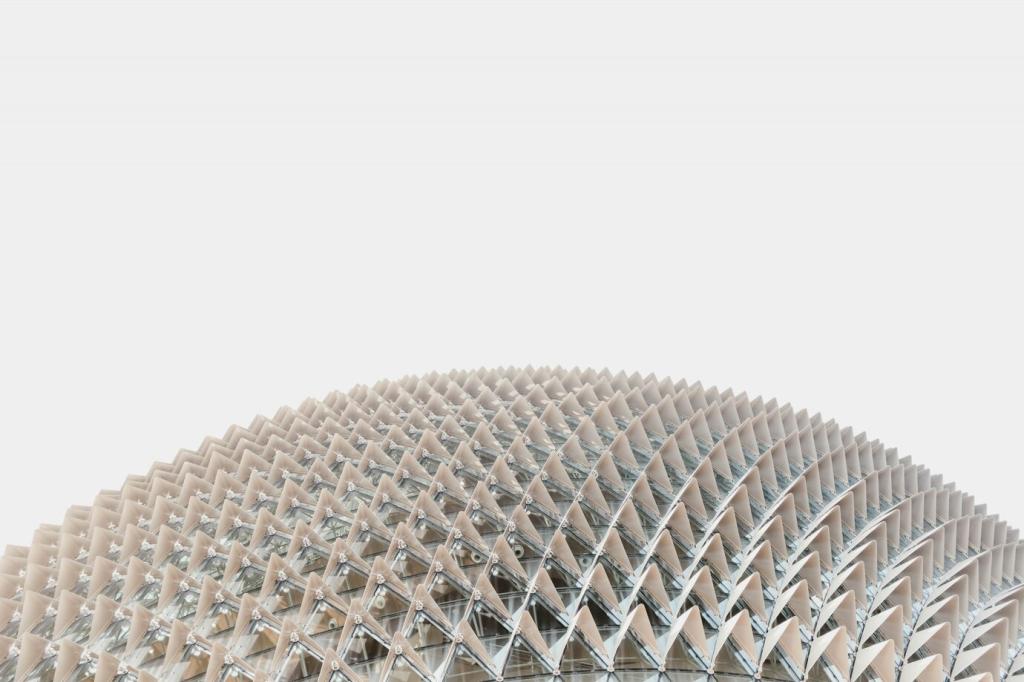

Case Studies and Milestones Around the World

Nonprofits and startups have collaborated on printed homes for families in need, proving speed and livability in real communities. Local crews trained on-site, creating jobs and know-how. Community feedback guided improvements to porches, shading, and room layouts. Which pilot model should be scaled next?

Case Studies and Milestones Around the World

Across Europe, occupied printed houses validated comfort, weathering, and inspection workflows. Teams refined mixes for cooler, wetter climates and standardized details for windows and services. Residents reported quiet interiors and steady temperatures, strengthening the case for broader deployment in similar environments.